Table of Contents

Smart Packaging Without Electronics: What's Possible?

While electronic components in packaging capture headlines, truly innovative smart packaging doesn't always require batteries or circuits. From temperature-sensitive inks to moisture-control materials, non-electronic smart packaging offers practical solutions that enhance product integrity, consumer safety, and brand engagement without the cost and complexity of digital technology.

Defining Smart Packaging Beyond Electronics

Smart packaging refers to any packaging system that provides functionality beyond basic containment and protection. While electronic solutions like RFID tags and NFC chips have revolutionized tracking and authentication, as detailed in this overview of RFID and NFC technologies, non-electronic approaches offer accessible alternatives with minimal environmental impact.

These solutions typically fall into two categories: active packaging that interacts with the product to extend shelf life or improve quality, and intelligent packaging that communicates information about the product condition without necessarily altering it.

Passive Indicators: Chemical and Physical Solutions

Thermochromic Inks

Temperature-sensitive inks change color when exposed to specific temperature ranges, providing visual indicators of product freshness or proper storage conditions. These inks require no power source yet effectively communicate critical information to consumers.

Time-Temperature Indicators (TTIs)

TTIs use chemical reactions to track cumulative temperature exposure over time. For perishable products, these indicators can show whether items have been stored properly throughout the supply chain, all without electronics.

Interactive Elements Without Circuits

Physical interactivity engages consumers without digital components. As explored in this article on interactive packaging, creative structural design can transform the unboxing experience into a memorable brand moment.

QR codes bridge the gap between physical and digital without requiring electronics in the packaging itself. By incorporating QR codes as calls to action, brands can deliver digital experiences through static printed elements.

Shelf Life Extension Through Innovative Materials

Oxygen Scavengers

These materials actively remove oxygen from package headspace, preventing oxidation and extending product shelf life. Unlike electronic monitoring systems, oxygen scavengers work continuously without power requirements.

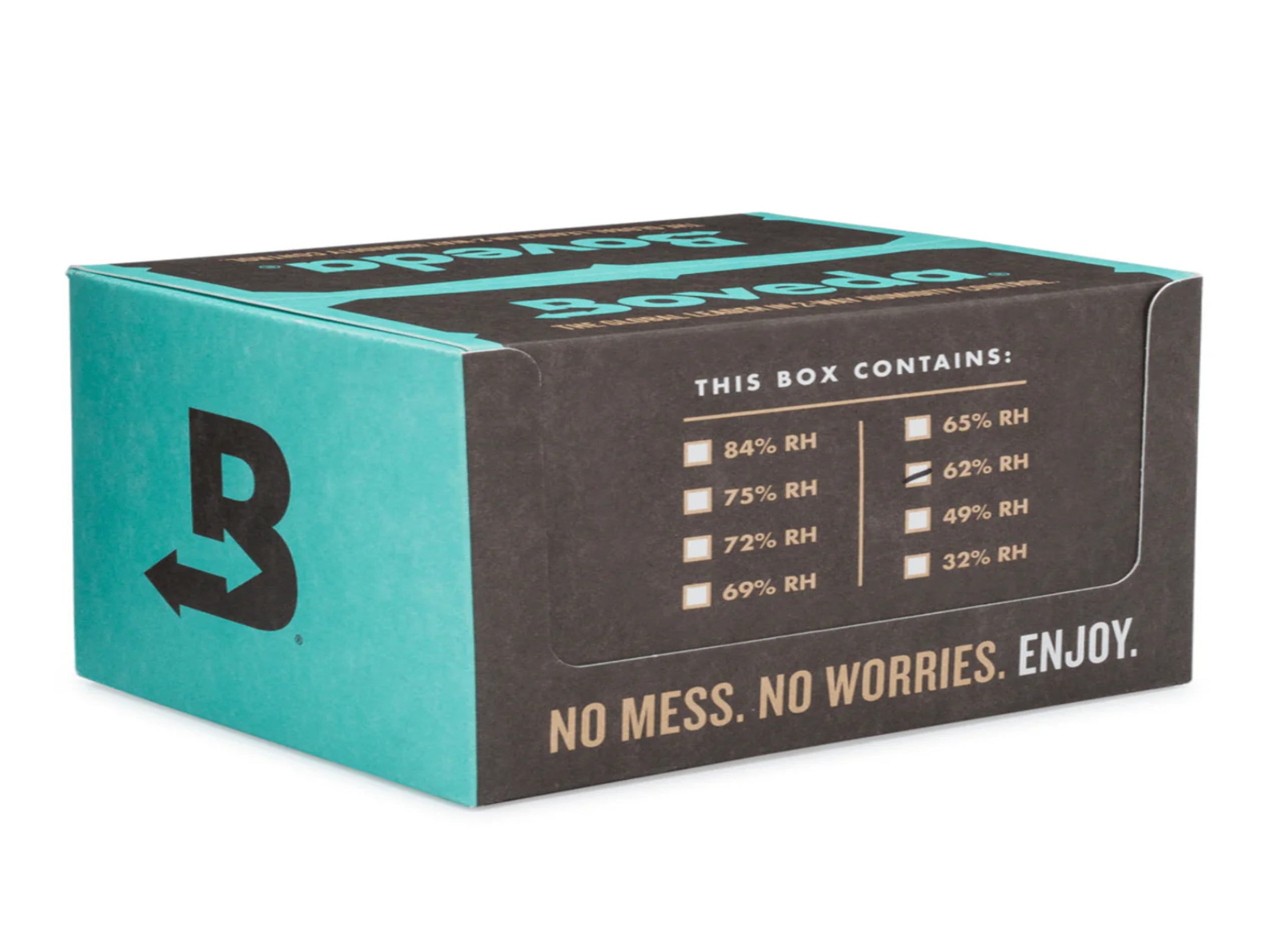

Moisture Control Solutions

Desiccants and humidity regulators maintain optimal moisture levels within packaging. For cannabis products specifically, these solutions help preserve potency and prevent mold growth, as highlighted in this guide to freshness-extending packaging.

Safety and Compliance Features

Smart packaging often incorporates safety features that protect consumers without electronic components. For example, specialized safety closures and child-resistant lids use mechanical design principles to create packaging that meets regulatory requirements while remaining accessible for intended users.

Tamper-evident features like breakable seals, perforated bands, and specialized adhesives provide visual indicators of package integrity without electronic monitoring. These solutions are particularly important in regulated industries like cannabis and pharmaceuticals.

Authentication Features

Holograms, color-shifting inks, and microtext provide authentication without electronics. These features help consumers and retailers verify product authenticity, addressing counterfeiting concerns in premium product categories.

- Specialized printing techniques that are difficult to replicate

- Unique material combinations that create distinctive textures or appearances

- Optical variables that change appearance when viewed from different angles

- Microperforations that create distinctive patterns when held up to light

Future Innovations in Non-Electronic Smart Packaging

The future of non-electronic smart packaging lies in biodegradable smart materials that provide functionality without environmental impact. Innovations in material science are creating packaging that responds to environmental conditions while remaining fully compostable.

As explored in this forward-looking analysis, hybrid approaches that combine minimal electronics with sustainable materials represent a promising direction. These solutions might incorporate thin, printable sensors on biodegradable substrates or use naturally reactive materials that change properties based on product conditions.

Smart packaging without electronics demonstrates that innovation doesn't always require complex technology. Through clever design, reactive materials, and thoughtful engineering, packaging can communicate, protect, and engage without batteries or circuits. As sustainability concerns grow, these low-tech smart solutions may ultimately prove more forward-thinking than their electronic counterparts.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.