A heat sealer is an essential tool for businesses that rely on flexible packaging to maintain product freshness, prevent tampering, and ensure a polished, retail-ready appearance. Whether you're packaging cannabis, food products, supplements, or industrial components, using a dedicated heat sealing machine improves efficiency and protects your inventory. For operators working specifically with laminated or foil-lined bags, a mylar bag sealer or mylar bag sealing machine offers precise, repeatable results that meet compliance and branding needs.

What Is a Heat Sealer?

A heat sealer is a machine that uses controlled heat and pressure to bond thermoplastic materials together. It creates an airtight seal along the edge of a bag or pouch, closing the package securely. Sealing can be done through impulse heat (only heating when pressure is applied) or constant heat, depending on the material and machine design.

- Impulse Sealers: Heat only when activated, suitable for light to medium gauge materials like polyethylene or mylar

- Constant Heat Sealers: Maintain continuous heat for thicker materials or foil laminates

- Foot Pedal or Automatic Models: Designed for increased throughput in semi- or fully automated lines

Types of Mylar Bag Sealing Machines

Mylar is a common packaging material used for high-barrier protection against light, air, and moisture. Sealing it correctly requires a specific type of machine designed to penetrate the layered material without damaging it. The most effective mylar bag sealing machine models include:

- Tabletop Impulse Sealers: Compact and portable, ideal for small operations and short runs

- Foot Pedal Sealers: Provide hands-free operation with more control over timing and pressure

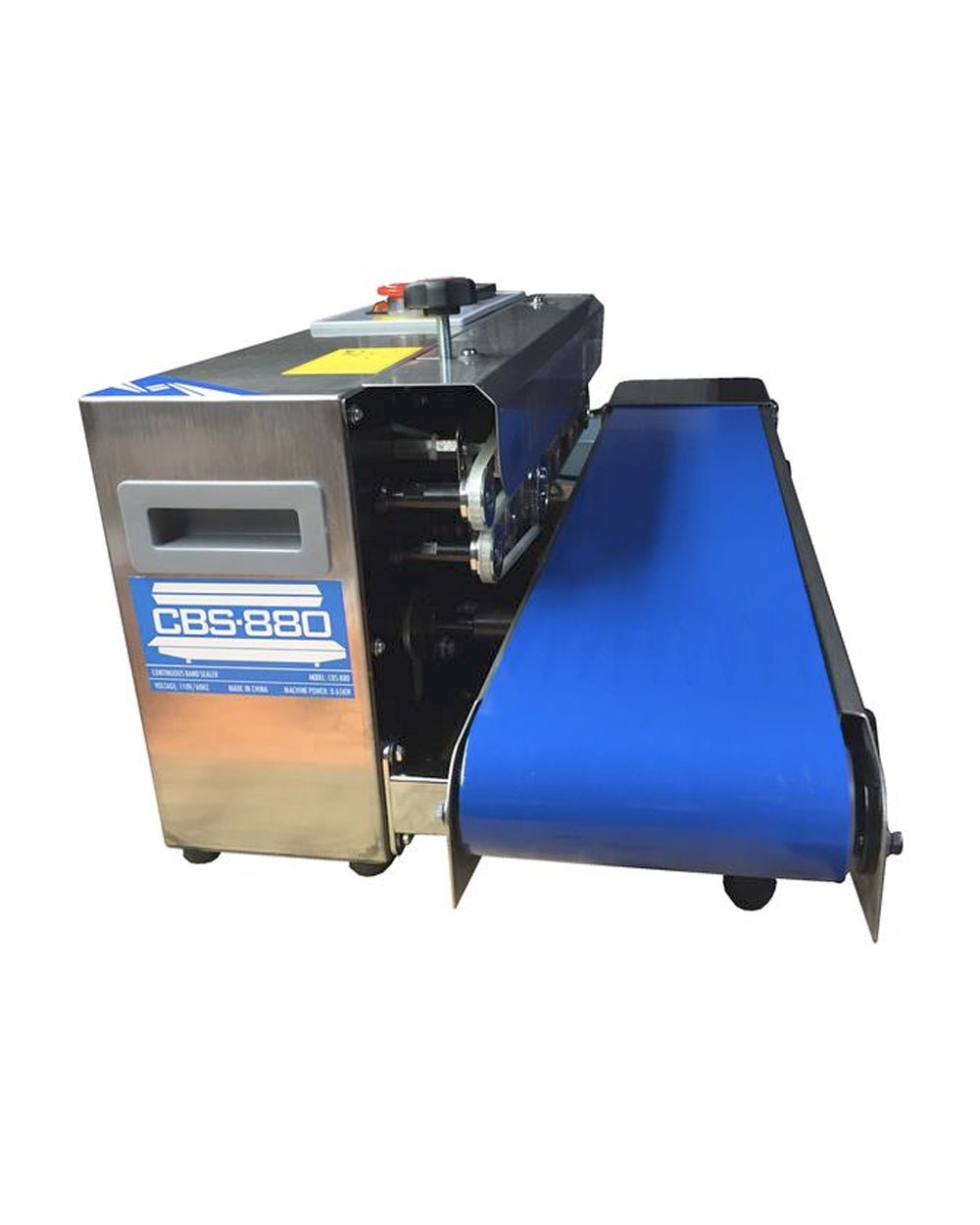

- Band Sealers: Continuous sealers used in higher volume operations for rapid sealing of multiple bags

- Vacuum Heat Sealers: Remove air before sealing, extending shelf life for perishable products

Choosing the right machine depends on production speed, bag type, product content, and compliance requirements.

Key Benefits of Using a Heat Sealing Machine

Investing in a reliable heat sealing machine helps businesses improve efficiency, reduce spoilage, and present their products professionally. Core benefits include:

- Airtight Seals: Preserves freshness, prevents leaks, and extends shelf life

- Tamper-Evident Packaging: Provides visible indicators of product integrity for consumers and retailers

- Speed and Efficiency: Streamlines production, especially when compared to manual closures or adhesive seals

- Consistency: Eliminates guesswork in sealing, resulting in fewer defective packages

- Compliance Support: Helps meet packaging laws in food, pharmaceutical, and cannabis industries

Applications Across Multiple Industries

Heat sealers are used in a wide range of industries where product safety, freshness, and presentation matter:

- Cannabis: Sealing flower, edibles, concentrates, or infused products in tamper-evident mylar bags

- Food & Beverage: Sealing snack bags, dry goods, frozen items, and ingredients in moisture-resistant pouches

- Cosmetics: Packaging bath salts, powders, or small tools in resealable, hygienic containers

- Healthcare: Protecting sterile products, test kits, or supplements from environmental contamination

- Electronics & Industrial: Shielding sensitive components from static, moisture, or dust

Factors to Consider When Selecting a Mylar Bag Sealer

Choosing the right mylar bag sealer involves assessing your operation’s volume, space, and material requirements:

- Seal Width and Length: Ensure the machine can accommodate the size of your bags

- Heat and Timer Controls: Adjustable settings improve precision across various materials

- Durability and Maintenance: Industrial-grade machines offer longer lifespans with fewer breakdowns

- Footprint: Choose a model that fits your workspace without interrupting workflow

- Integration: Some sealers can be integrated into conveyor systems or packaging lines

Best Practices for Using a Heat Sealer

To get the most out of your sealing machine, follow these usage and maintenance guidelines:

- Keep sealing bars clean and free of debris or product residue

- Perform routine checks on heating elements and silicone pads

- Test seals regularly to ensure consistent pressure and closure

- Use the right seal time and temperature based on bag material thickness

- Train staff on safe handling, especially for high-temperature or foot-operated models

These steps help maintain quality control while reducing machine downtime and material waste.

Conclusion: Elevate Packaging Standards with Heat Sealers

Whether you're packaging cannabis products, food, cosmetics, or industrial parts, a high-quality heat sealer ensures your packaging meets today’s functional and regulatory standards. With airtight seals, reliable performance, and flexible integration options, mylar bag sealing machines help streamline operations while protecting the value of your product. As markets grow more competitive, leveraging professional-grade sealing equipment becomes a strategic advantage in both presentation and preservation.