Table of Contents

Innovations in Protective Packaging for Fragile Items

The protective packaging industry continues to evolve rapidly as manufacturers seek better ways to shield delicate products from damage during transit and storage. From advanced cushioning materials to ingenious structural designs, these innovations not only protect products but also address growing concerns around sustainability and user experience.

Evolution of Protective Packaging

Protective packaging has come a long way from simple paper wrapping and wooden crates. Today's solutions incorporate sophisticated engineering principles and material science to create barriers against impact, vibration, temperature fluctuations, and moisture. The evolution has been driven by e-commerce growth, which has dramatically increased the need for packages that can withstand complex logistics networks.

According to industry reports, damage rates decrease by up to 70% when appropriate protective packaging is implemented. Smarter packaging materials not only protect products but also reduce returns and enhance customer satisfaction.

Advanced Materials Transforming Protection

Air-Based Cushioning Systems

Modern air pillows and bubble wraps now feature engineered air chambers that distribute impact forces more effectively than their predecessors. These systems can be inflated on-demand, reducing storage space requirements by up to 90% compared to pre-inflated alternatives.

Moldable Foam Technologies

Custom-molded foam inserts provide product-specific protection by creating perfect-fit cavities that immobilize items during transit. Recent innovations include:

- Memory foams that absorb and dissipate impact energy

- Anti-static formulations for electronics protection

- Temperature-resistant variants for sensitive pharmaceuticals

- Biodegradable foam alternatives made from cornstarch and mushroom mycelium

Smart Design Solutions

Beyond materials, packaging design itself has become more sophisticated. Suspension packaging suspends products in the center of the outer container using tensioned films or membranes. This creates a floating effect that isolates products from exterior impacts.

Another innovation is the development of weatherproof packaging solutions that protect contents from environmental factors like rain, humidity, and temperature extremes. These designs incorporate moisture barriers, thermal insulation, and specialized sealing methods.

Safety Standards and Regulatory Compliance

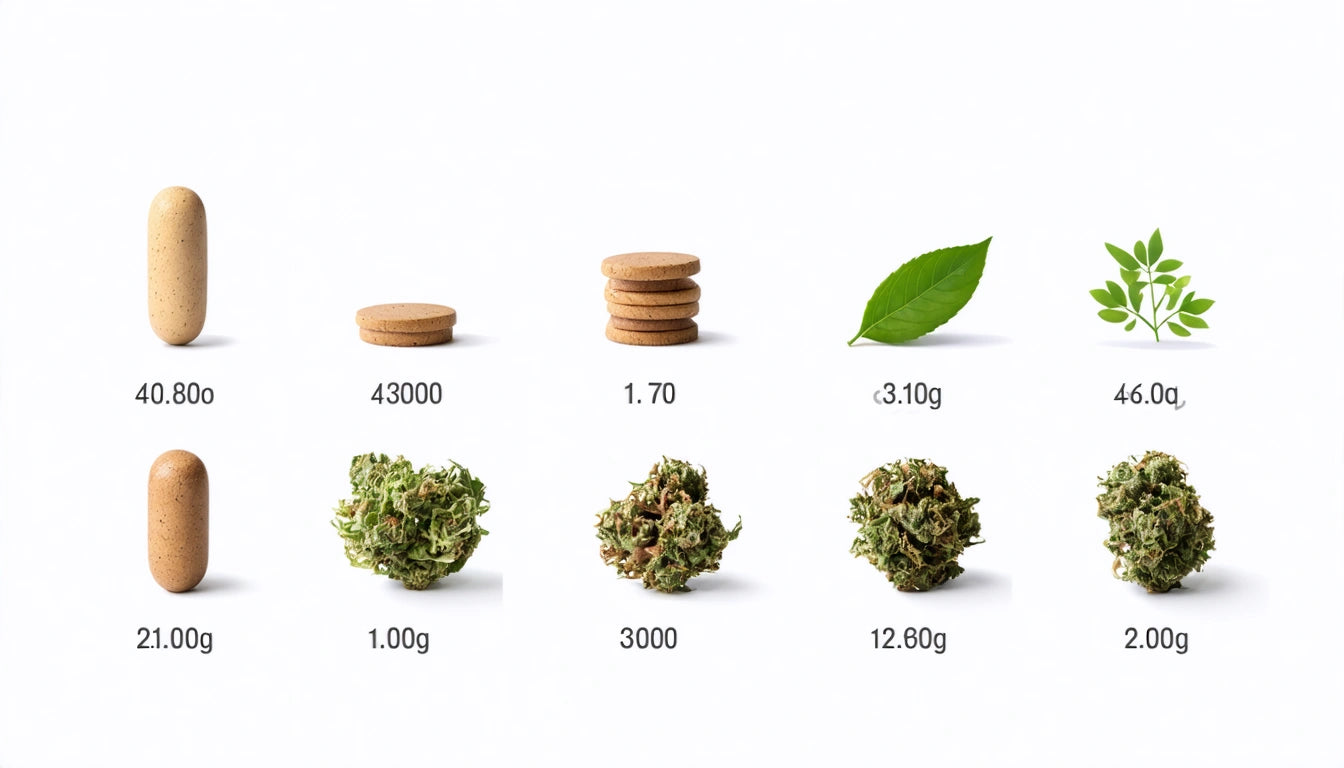

Protective packaging must often meet stringent safety standards, particularly for hazardous or sensitive products. Child-resistant packaging represents one of the most important safety innovations in this field. Federal safety regulations require special packaging designs that prevent children under five from accessing harmful contents while remaining accessible to adults, significantly reducing accidental poisonings since implementation.

These specialized designs employ mechanisms like push-and-turn caps, alignment arrows, or multiple simultaneous actions that exceed a young child's cognitive and physical capabilities. The effectiveness of these designs is tested through protocols where children attempt to access the contents within a specified timeframe.

Sustainable Approaches to Protective Packaging

Plant-Based Cushioning

Innovative companies are now creating protective packaging from agricultural byproducts and fast-growing plants. Examples include:

- Molded pulp trays from recycled paper or bagasse (sugarcane waste)

- Cornstarch-based packing peanuts that dissolve in water

- Seaweed-based wrapping that biodegrades rapidly

- Hemp fiber cushioning with natural shock-absorbing properties

Reusable Protection Systems

The shift toward circular economy principles has inspired reusable protective packaging systems. These include returnable shipping containers with integrated protection and multi-trip packaging designed to maintain its protective properties through numerous cycles.

As detailed in this comprehensive guide to protective packaging innovations, companies implementing reusable systems have reported up to 60% cost savings over single-use alternatives when measured across multiple shipments.

Future Innovations in Protective Packaging

Looking ahead, several emerging technologies promise to further transform protective packaging:

- Smart packaging with embedded sensors that detect and record impacts, temperature violations, or moisture exposure during transit

- Self-healing materials that can repair minor tears or punctures automatically

- Phase-change materials that maintain specific temperature ranges for sensitive products

- 3D-printed custom protection created on-demand for uniquely shaped items

These innovations represent not just incremental improvements but fundamental shifts in how we approach product protection. The most successful protective packaging solutions will be those that balance physical protection with sustainability concerns, regulatory compliance, and enhanced user experience.

As e-commerce continues to grow and supply chains become increasingly complex, investment in advanced protective packaging will remain essential for companies seeking to minimize damage, reduce returns, and enhance customer satisfaction while meeting environmental responsibilities.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.