Table of Contents

How to Integrate Indicator Cards in Bulk Packaging

Maintaining optimal humidity levels in bulk cannabis storage is critical for product quality, shelf life, and compliance. Integrating humidity indicator cards into your packaging workflow provides real-time monitoring capabilities that can prevent costly product degradation. This guide explores practical methods for incorporating these essential tools into your bulk packaging operations.

Understanding Indicator Cards: Purpose and Function

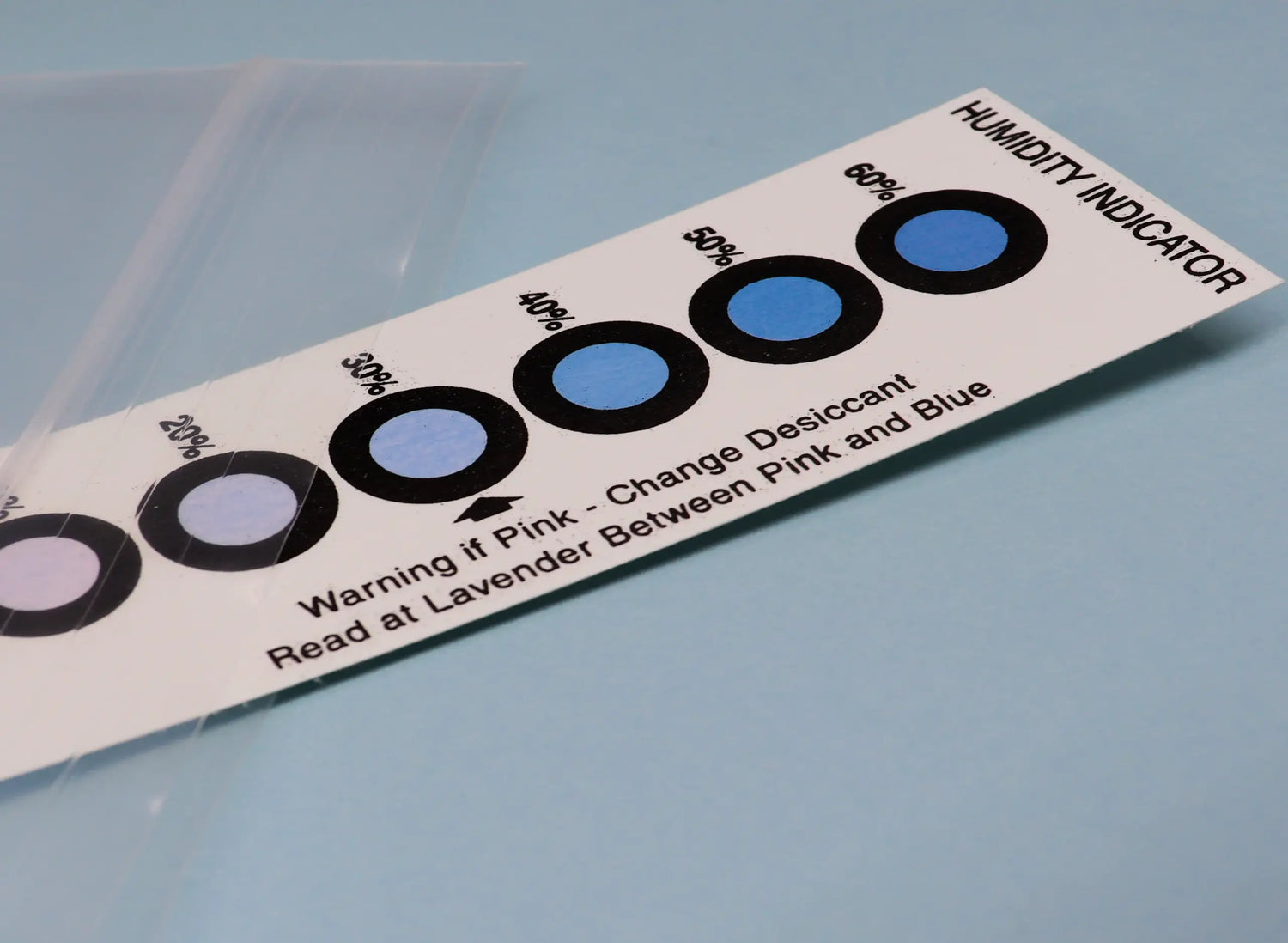

Humidity indicator cards serve as visual monitoring tools that change color to reflect moisture levels within a sealed environment. Unlike humidity control packs that actively regulate moisture, indicator cards simply report current conditions, allowing for quick assessment without opening containers.

These cards typically feature moisture-sensitive spots that change from blue (dry) to pink (humid) at specific relative humidity (RH) thresholds. Most cannabis applications utilize cards with indicators at 30%, 40%, 50%, and 60% RH points, providing granular insight into storage conditions.

Selecting the Right Indicators for Bulk Storage

Card Specifications for Cannabis Storage

When selecting indicator cards for cannabis bulk packaging, consider these key factors:

- Size and visibility: Cards should be easily visible through packaging or placed strategically for quick checks

- Sensitivity range: Cards should include indicators around the 55-62% RH range, which is optimal for cannabis storage

- Reversibility: Some cards change back when conditions normalize, while others provide permanent records of exposure

- Quantity per package: For large bulk containers, multiple cards may be needed for accurate monitoring

For operations using Integra Boost humidity control packs, coordinating your indicator cards with the appropriate RH level is essential. This guide on choosing between 55% and 62% RH levels can help determine which indicator thresholds will be most relevant for your products.

Implementation Strategies for Bulk Packaging

Card Placement Techniques

Strategic placement of indicator cards is crucial for effective monitoring. For bulk storage in large mylar storage bags, consider these implementation methods:

- Perimeter monitoring: Place cards at various points around the container's perimeter

- Layer insertion: For deep containers, insert cards at different depths to monitor stratified conditions

- Entry point focus: Position cards near seals or openings where humidity fluctuations are most likely

- Attachment methods: Use food-safe adhesives or integrated pockets to secure cards

When working with humidity control packs, position indicator cards at a distance from the packs to get an accurate reading of the overall environment rather than just the area immediately surrounding the humidity pack.

Monitoring and Maintenance Protocols

Establishing consistent monitoring protocols ensures you capture meaningful data from your indicator cards:

Documentation Systems

Create a standardized logging system that records:

- Date and time of each check

- Current indicator readings

- Any environmental factors that might impact readings

- Actions taken in response to readings

Many operations incorporate this monitoring into their quality assurance procedures, creating a documented history that can support compliance requirements and process improvements.

Replacement Schedules

Even the best indicator cards have limited lifespans. Establish replacement schedules based on:

- Manufacturer recommendations

- Environmental exposure

- Handling frequency

- Visual degradation of the card itself

Most cards should be replaced every 3-6 months in active storage environments, though some premium options may last longer. For guidance on humidity pack replacement, this resource on Integra pack replacement timing offers valuable insights.

Cost-Efficiency Analysis of Indicator Integration

Implementing indicator cards represents a minimal investment compared to the potential savings from prevented product loss. Consider these economic factors:

Direct Costs vs. Preventative Value

A typical indicator card costs between $0.50-$2.00, depending on quality and quantity purchased. When integrated with comprehensive humidity control solutions, these cards can help prevent thousands of dollars in product degradation.

The math is compelling: a $1 indicator card that prevents even a single ounce of product from developing mold represents a significant return on investment. As outlined in this analysis of cost savings from proper humidity control, the preventative value far outweighs the implementation costs.

Integration with Existing Systems

For maximum efficiency, integrate indicator card monitoring with your existing inventory management and quality control systems. This might include:

- Adding indicator status to inventory tracking software

- Incorporating card checks into regular quality assurance procedures

- Training staff on proper interpretation and response protocols

- Documenting findings for compliance and process improvement

By systematizing this process, you convert simple visual indicators into actionable business intelligence that protects product quality and supports regulatory compliance.

Future Applications and Technology Trends

The field of environmental monitoring in cannabis storage continues to evolve. Forward-looking operations are already exploring:

- Digital humidity indicators with Bluetooth connectivity for remote monitoring

- Integration with environmental control systems for automated responses

- Combined indicator systems that monitor multiple environmental factors

- Sustainable indicator options with reduced environmental impact

As regulations evolve and quality standards become more stringent, the role of indicator cards in bulk packaging will likely expand from simple monitoring tools to essential components of comprehensive quality management systems.

By implementing these strategies for indicator card integration, cannabis businesses can enhance their quality control processes, extend product shelf life, and demonstrate their commitment to delivering consistent, high-quality products to their customers.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.