Table of Contents

- Packaging Fail #1: Inadequate Moisture Control

- Packaging Fail #2: Non-Compliant Child-Resistant Features

- Packaging Fail #3: Poor Terpene Preservation

- Packaging Fail #4: Ineffective Odor Control

- Packaging Fail #5: Overlooking Branding Opportunities

- Strategic Packaging Investments for Long-Term Success

In the competitive cannabis market, packaging mistakes can cost brands significantly in product quality, compliance penalties, and lost customer loyalty. Understanding the most common packaging failures helps producers avoid costly mistakes while enhancing product presentation and preservation. Let's explore the five most frequent cannabis flower packaging fails and practical solutions to address them.

Packaging Fail #1: Inadequate Moisture Control

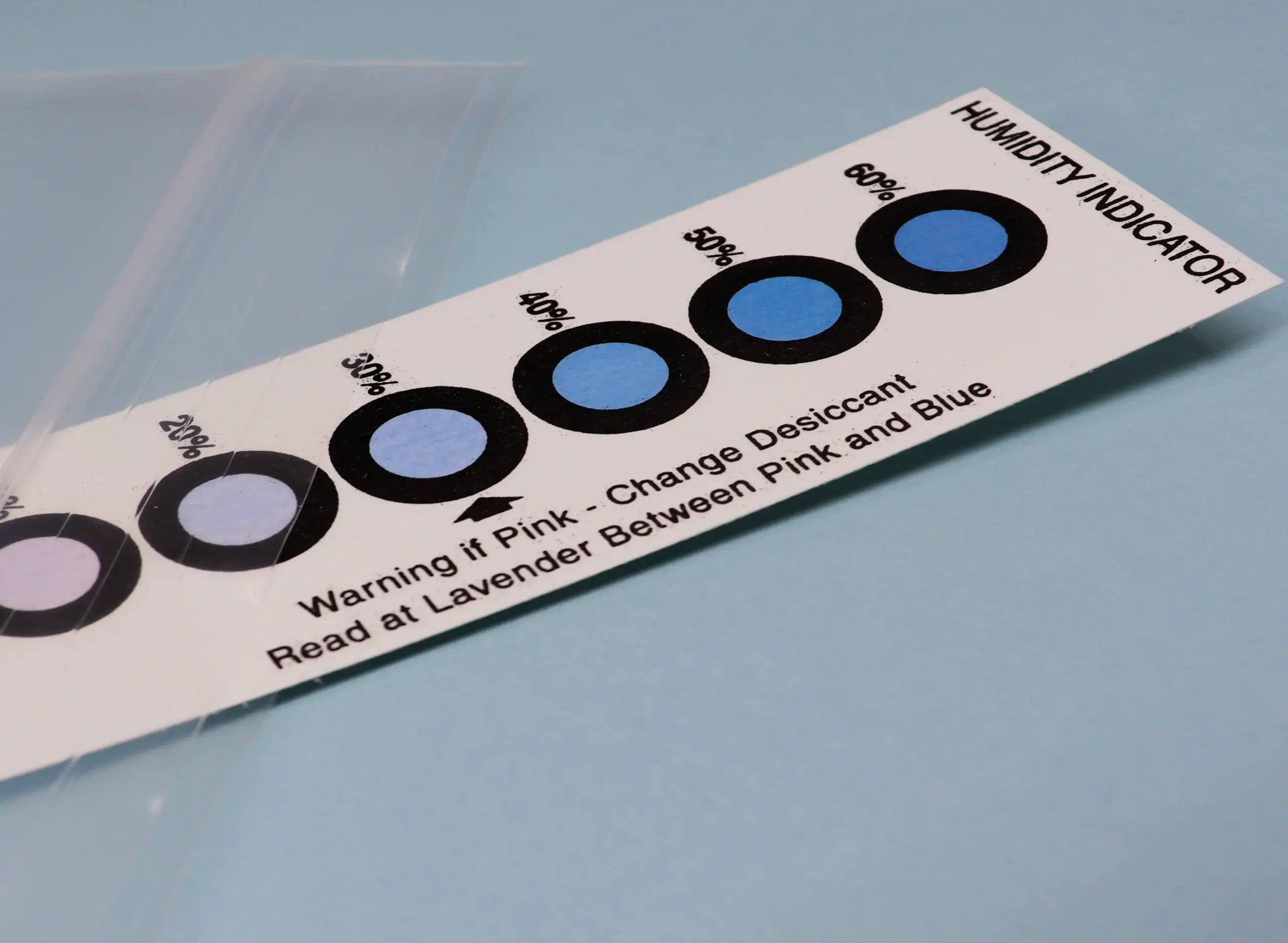

Moisture management remains one of the most critical yet overlooked aspects of cannabis flower packaging. Too much humidity promotes mold growth, while too little causes flower to become brittle and lose potency. Both scenarios lead to disappointed customers and potential product returns.

The Solution:

Integrate humidity control packs into your packaging strategy. Research shows that properly calibrated humidity packs maintain optimal moisture levels between 58-62%, significantly extending shelf life. Additionally, selecting appropriate container materials matters tremendously.

According to this comparison of glass jars versus mylar bags, glass provides superior humidity stability for premium flower, while quality mylar with proper sealing works well for standard products. The key is matching your packaging solution to your product positioning and price point.

Packaging Fail #2: Non-Compliant Child-Resistant Features

Compliance failures represent the most costly packaging mistakes, potentially resulting in product recalls, fines, and even license suspension. Child-resistant packaging requirements vary by state but remain universally mandatory in the cannabis industry.

The Solution:

Invest in properly certified child-resistant packaging that meets CPSC standards and your specific state requirements. Many brands find that specialized child-resistant closures and lids offer the perfect balance of safety and usability, allowing for compliant packaging that consumers can still open without frustration.

Beyond basic compliance, consider how your child-resistant features integrate with your overall design. Stylish child-resistant packaging is entirely possible with today's innovative solutions that maintain safety without sacrificing aesthetics.

Packaging Fail #3: Poor Terpene Preservation

Terpenes, the aromatic compounds that give cannabis its distinctive smell and contribute to its effects, are highly volatile. Improper packaging allows these valuable compounds to degrade rapidly, resulting in diminished aroma, flavor, and potentially altered effects.

The Solution:

Select packaging materials that create effective barriers against light, heat, and air exposure, the primary culprits of terpene degradation. Proper terpene preservation techniques include using UV-resistant glass or opaque materials and ensuring airtight seals.

For brands focusing on terpene-rich strains, consider how your packaging communication highlights these valuable compounds. Educated consumers increasingly look for packaging that demonstrates an understanding of terpene preservation, viewing it as an indicator of overall product quality.

Packaging Fail #4: Ineffective Odor Control

While cannabis enthusiasts may appreciate the aroma of quality flower, odor leakage creates problems for discrete consumers and retailers managing inventory. Ineffective odor control can limit where and how consumers use your products and may even violate certain housing or public space regulations.

The Solution:

Implement multi-layer packaging strategies using proven odor-proof materials like specialized films with activated carbon layers or multiple-seal systems. The best odor-control packaging prevents smell leakage without trapping harmful gases that could affect flower quality.

For bulk producers and distributors, odor control becomes even more critical. Best practices for bulk packaging include using industrial-grade odor-barrier materials and considering how packaging will perform during transportation and storage.

Packaging Fail #5: Overlooking Branding Opportunities

Generic or poorly designed packaging fails to differentiate products in increasingly crowded dispensary environments. Many producers focus exclusively on compliance and preservation while neglecting the critical marketing function of their packaging.

The Solution:

Develop packaging that serves as a brand ambassador through thoughtful design elements, consistent visual language, and strategic information hierarchy. Studies show that effective branding on cannabis packaging significantly impacts purchasing decisions and price perception.

Consider how your packaging communicates your brand values, whether that's sustainability, premium quality, or specific effects. Consumer trends research indicates buyers increasingly look for packaging that aligns with their personal values while clearly communicating product attributes.

Strategic Packaging Investments for Long-Term Success

Avoiding these common packaging fails requires viewing packaging as a strategic investment rather than a mere necessity. The most successful cannabis brands understand that packaging serves multiple critical functions: product preservation, regulatory compliance, brand communication, and user experience.

When evaluating packaging solutions, consider the full lifecycle of your product from production to consumer use. Reclosable packaging options enhance the user experience while maintaining freshness throughout the consumption period.

For brands committed to sustainability, explore eco-friendly packaging alternatives that align with both environmental values and product preservation requirements. The growing consumer preference for sustainable options makes this an increasingly important consideration.

Finally, remember that packaging requirements evolve alongside regulations and market expectations. Staying informed about state-specific packaging requirements and emerging consumer preferences positions your brand to adapt quickly and maintain both compliance and market relevance.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.