Table of Contents

Chubby Gorilla's Spring Mechanism: Engineering Child-Safety That Clicks

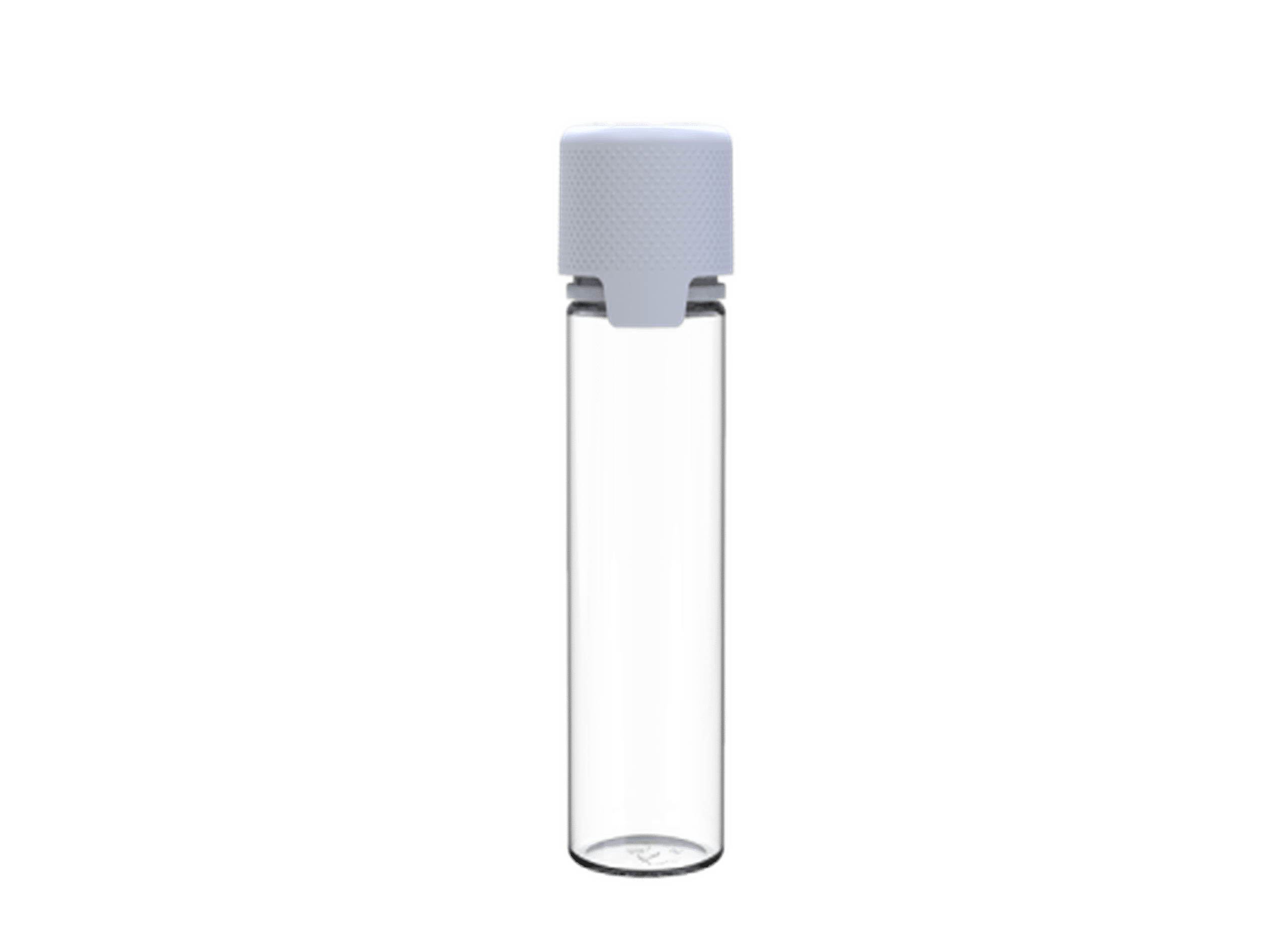

Child-resistant packaging represents a critical safety feature in cannabis, pharmaceutical, and chemical industries. Among the leaders in this space, Chubby Gorilla has developed a spring mechanism that has become the industry standard for reliable child-resistant containers (CRC). This engineering marvel balances the dual requirements of being difficult for children to access while remaining accessible for adults.

Understanding Chubby Gorilla's Spring Mechanism

At the heart of Chubby Gorilla's product line is a precision-engineered spring mechanism that creates the signature "click" when properly engaged. This system relies on internal compression springs that require a specific sequence of actions to open, typically involving pushing down while turning. The mechanism is calibrated to require a level of dexterity and strength that exceeds the capabilities of young children.

The spring mechanism features:

- Compression-resistant metal springs

- Interlocking teeth that engage when closed

- Calibrated resistance that meets regulatory standards

- Audible feedback (the "click") confirming proper closure

Engineering Principles Behind the Click

Material Science

The durability of Chubby Gorilla's spring mechanism depends on material selection. The company primarily uses medical-grade plastics for the housing and high-tensile metal for the springs. This combination ensures the mechanism maintains its resistance level even after hundreds of uses. The SmartCap technology exemplifies this engineering approach with its reliable performance over extended periods.

Precision Tolerances

Manufacturing precision is crucial for consistent performance. Chubby Gorilla maintains tight tolerances in production, ensuring that components fit together with minimal variation. This precision is particularly evident in their gapless seal design, which creates a secure closure while maintaining the spring mechanism's functionality.

Compliance and Testing Standards

Chubby Gorilla's spring mechanism is designed to meet or exceed regulatory requirements across multiple jurisdictions. The engineering process involves rigorous testing to ensure compliance with standards such as:

- CPSC (Consumer Product Safety Commission) guidelines

- 16 CFR 1700 (Poison Prevention Packaging Act)

- ISO 8317 international standards for reclosable child-resistant packaging

Testing protocols involve both child-testing panels (to ensure children cannot open the containers) and senior-adult testing panels (to confirm adults can open them without difficulty). These dual requirements create engineering challenges that Chubby Gorilla addresses through their spring mechanism design, as detailed in their approach to ISO 8317 compliance.

Practical Applications Across Industries

While cannabis packaging represents a significant market for Chubby Gorilla's products, their spring mechanism technology finds applications across multiple industries:

Cannabis and CBD

The cannabis industry has widely adopted Chubby Gorilla containers for their reliability and compliance features. Products like the Unicorn bottles have become standard for CBD vape liquids, where child safety is paramount. When handling these products, many operators also use precision digital scales for accurate dosing to ensure product consistency alongside safety.

Pharmaceutical Applications

The pharmaceutical industry benefits from the same spring mechanism technology for prescription medications. The consistent performance and senior-friendly design make these containers ideal for medications that must remain inaccessible to children while being usable by adults who may have dexterity limitations.

Chemical Products

Household chemicals and potentially harmful substances utilize similar spring mechanism designs to prevent accidental exposure. The engineering principles applied in Chubby Gorilla's Aviator containers demonstrate how the spring mechanism can be adapted for different product formulations and viscosities.

Balancing Safety and Accessibility

One of the most significant engineering challenges in child-resistant packaging is creating mechanisms that effectively block children while remaining accessible to adults, particularly seniors or those with physical limitations. Chubby Gorilla addresses this through:

- Ergonomic cap designs that provide better grip

- Calibrated spring tension that meets regulatory requirements without excessive force

- Visual and tactile indicators that guide proper usage

- The micro-grip diamond texture that improves handling

This balance is particularly evident in their approach to senior-friendly CRC design, which maintains child resistance while accommodating users with limited hand strength or dexterity.

Innovation Pathway and Future Developments

Chubby Gorilla continues to refine their spring mechanism technology, with several notable improvements in recent generations. The evolution from earlier versions to Version 3 bottles demonstrates their commitment to continuous improvement.

Future developments may include:

- Integration with smart packaging technologies for compliance tracking

- Biodegradable materials that maintain spring mechanism performance

- Further refinements to improve accessibility while maintaining safety

- Advanced tamper-evident features that work in concert with the spring mechanism

As regulations continue to evolve across industries, Chubby Gorilla's engineering approach to child-resistant packaging provides a foundation for adaptation and innovation. Their spring mechanism represents not just a technical solution but a comprehensive approach to safety that balances regulatory compliance with practical usability.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.