Table of Contents

- Understanding Banding Machines: Types and Applications

- Preparing Your Banding Machine for Operation

- Step-by-Step Operation Guide

- Creating Perfect Bands: Techniques and Best Practices

- Troubleshooting Common Issues with Banding Machines

- Maintenance Tips for Longevity and Performance

- Packaging Innovations: Beyond Basic Banding

Mastering Banding Machines: A Guide to Effective Usage and Techniques

Banding machines have revolutionized packaging efficiency across multiple industries, particularly in cannabis product packaging. These versatile tools secure products with paper or plastic bands, creating a professional finish while maintaining product integrity. Whether you're new to using a banding machine or looking to refine your technique, this comprehensive guide will help you master the art of banding.

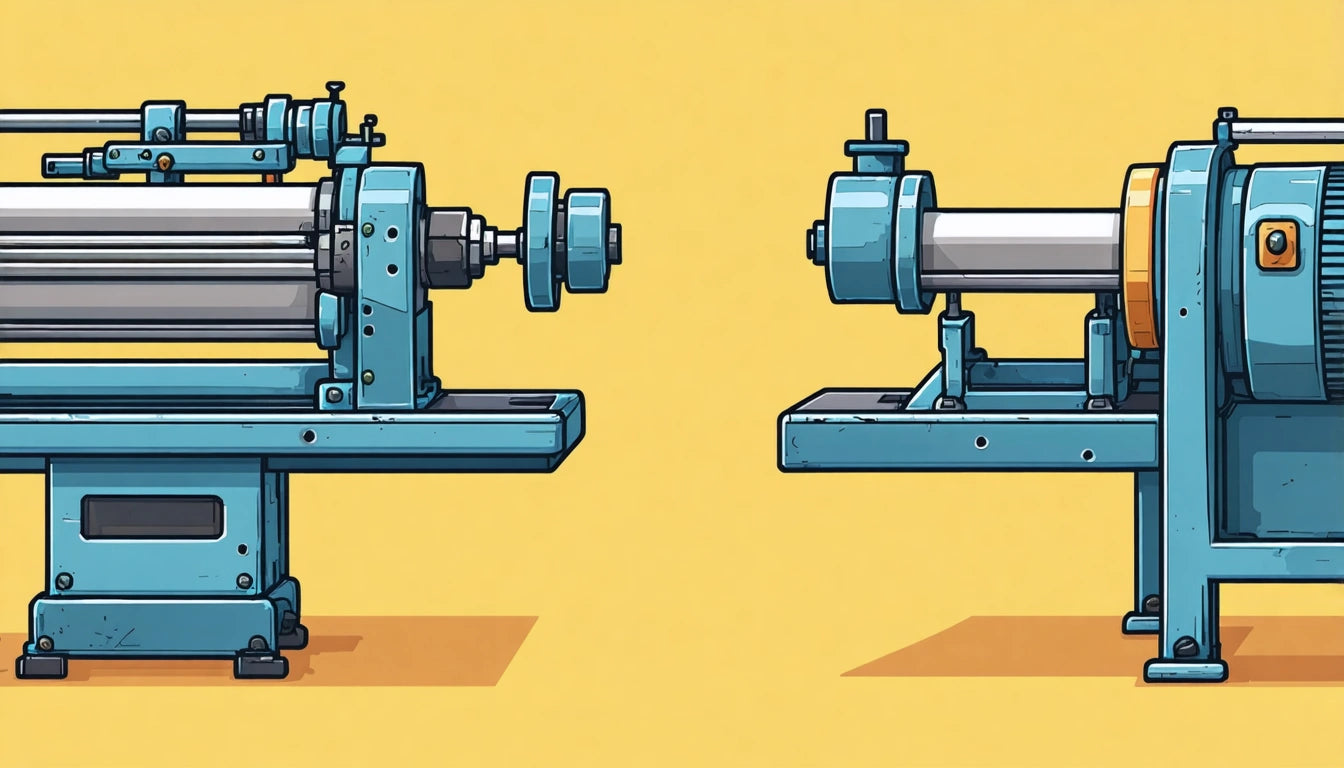

Understanding Banding Machines: Types and Applications

Banding machines come in several varieties, each designed for specific applications. The most common types include:

- Automatic banding machines: High-volume operations with minimal operator intervention

- Semi-automatic banders: Requiring some manual feeding but automating the banding process

- Manual banding tools: Cost-effective solutions for smaller operations

In the cannabis industry, banding machines are particularly valuable for securing packaging for flower products, pre-rolls, and retail displays. Many dispensaries use banding to create tamper-evident seals on their eighth-ounce mylar packaging bags, which provides both security and professional presentation.

Preparing Your Banding Machine for Operation

Initial Setup

Before learning how to use a banding machine effectively, proper setup is essential:

- Place the machine on a stable, level surface

- Connect to a power source that meets the machine's specifications

- Install the correct band material for your application

- Adjust the tension settings according to product requirements

- Set the appropriate heat level for proper band sealing

Loading Band Material

Proper loading of banding material is crucial for smooth operation:

- Open the material compartment according to manufacturer instructions

- Insert the band roll with the correct orientation

- Thread the material through the guide system

- Close all access panels securely

Step-by-Step Operation Guide

Learning how to use a bander efficiently requires understanding the basic operational sequence:

Basic Operation Sequence

- Power on the machine and allow it to reach operating temperature

- Position your product in the banding area

- Initiate the banding cycle (button, foot pedal, or sensor-triggered)

- Allow the machine to complete the band application

- Remove the banded product carefully

For semi-automatic machines, you'll need to manually place each item, while automatic systems may use conveyor feeds to streamline the process.

Creating Perfect Bands: Techniques and Best Practices

Mastering how to create band seals that are both secure and visually appealing requires attention to several factors:

Tension Control

The right tension ensures bands are tight enough to secure products without damaging them:

- Start with manufacturer-recommended settings

- Test on sample products before full production

- Increase tension gradually until optimal security is achieved

- Document successful settings for different product types

Band Width Selection

Choosing the appropriate band width impacts both security and aesthetics:

- Narrow bands (20-30mm): Ideal for smaller items or when minimal coverage is desired

- Medium bands (40-60mm): Standard for most packaging applications

- Wide bands (70mm+): Best for bundling multiple items or when bands include printed information

Similar to how crafters learn techniques for creating jewelry designs, mastering banding requires practice with different materials and widths to achieve professional results.

Troubleshooting Common Issues with Banding Machines

Even experienced operators encounter challenges when using banding machines. Here are solutions to common problems:

Band Breaks During Application

- Check for sharp edges on products that may cut bands

- Verify tension settings aren't too high

- Inspect the heating element for proper function

- Ensure band material is properly threaded

Inconsistent Seal Quality

- Clean the heating element regularly

- Adjust temperature settings

- Check for consistent pressure application

- Verify band material quality and compatibility

Feed Problems

- Clear any obstructions in the feed path

- Check for proper alignment of guide rollers

- Inspect for worn components that need replacement

- Ensure band material isn't expired or damaged

Maintenance Tips for Longevity and Performance

Regular maintenance ensures your banding machine operates efficiently for years:

Daily Maintenance

- Clean exposed surfaces and remove debris

- Check band path for obstructions

- Inspect heating elements for residue buildup

- Verify all safety features are functioning

Weekly Maintenance

- Lubricate moving parts according to manufacturer specifications

- Check electrical connections

- Clean sensors and photocells

- Inspect band tension system

Monthly Maintenance

- Conduct a comprehensive inspection of all components

- Replace worn parts before they fail

- Verify calibration of tension and heat settings

- Update maintenance logs for warranty purposes

Just as enthusiasts learn detailed maintenance procedures for cannabis accessories, banding machine maintenance should become a regular part of your operational routine.

Packaging Innovations: Beyond Basic Banding

Advanced users can leverage banding machines for creative packaging solutions:

Custom Printed Bands

Elevate your packaging with custom-printed bands featuring:

- Brand logos and colors

- Product information and batch codes

- QR codes linking to digital content

- Promotional messaging

Multi-layer Applications

Create sophisticated packaging by:

- Applying multiple bands in different orientations

- Combining different band widths for visual interest

- Using contrasting colors for emphasis

- Creating tamper-evident seals with strategic band placement

As the packaging industry evolves, banding machines continue to offer innovative solutions for product security, branding, and presentation. By mastering these techniques, you'll be well-equipped to create professional, secure packaging for any application.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.