Table of Contents

The Ultimate Guide to Choosing the Best Commercial Rosin Press

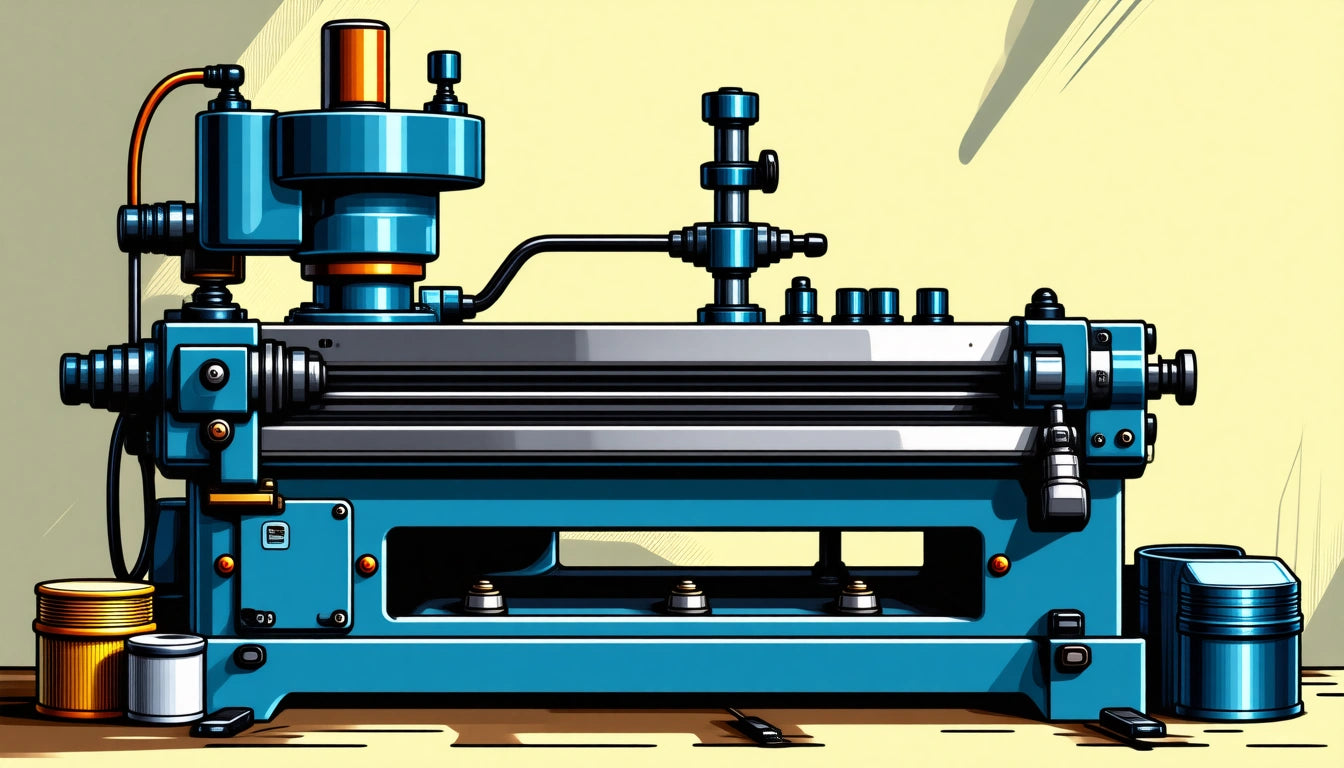

Selecting the best commercial rosin press is a critical decision for cannabis processors looking to produce high-quality solventless concentrates at scale. With numerous options available on the market, understanding the key differences between models can significantly impact your operation's efficiency, product quality, and bottom line.

Understanding Commercial Rosin Presses

Commercial rosin presses differ from personal or small-batch models in several important ways. These industrial-grade machines are designed for continuous operation, higher pressure capabilities, and larger processing capacities.

Unlike solvent-based extraction methods, rosin production uses only heat and pressure to extract cannabinoids and terpenes from plant material. This process creates a clean, solventless product that many consumers prefer, as explored in this comparison of solventless rosin vs. live rosin.

Types of Commercial Presses

- Pneumatic Presses: Utilize air compressors for consistent pressure

- Hydraulic Presses: Offer maximum pressure capabilities

- Electric Presses: Provide precise control and often feature programmable settings

- Hybrid Systems: Combine technologies for optimized performance

Commercial operations typically require presses that can handle between 20-50 tons of pressure, compared to the 3-10 tons sufficient for personal use.

Key Features to Consider When Choosing a Commercial Rosin Press

When evaluating the best rated rosin press options for commercial use, several factors should influence your decision:

Pressure Capacity

Pressure is measured in tons and directly impacts yield. Most commercial operations require at least 20 tons of pressure for efficient extraction. Higher pressure capabilities allow for processing larger quantities of material simultaneously.

Plate Size and Configuration

Larger plates accommodate more material per press cycle, increasing throughput. Look for even heat distribution across plates to ensure consistent quality. Some advanced models offer interchangeable plates for different batch sizes.

Temperature Control

Precise temperature regulation is crucial for preserving terpenes and achieving desired consistency. Top models offer digital controls with temperature ranges from 100-300 °F (38-149 °C).

Automation Features

Advanced commercial presses offer programmable cycles, pressure ramping, and automated release functions. These features improve consistency between batches and reduce operator fatigue during high-volume production days.

Top Rated Commercial Rosin Press Models

Based on industry feedback and performance metrics, these models consistently rank among the best commercial rosin presses:

Industrial Leaders

- PurePressure Longs Peak: Features 8" × 10" plates, 30 tons of pressure, and advanced automation

- Sasquash V2: Offers 20 tons of force with pneumatic operation and dual heating plates

- Rosinbomb Rocket: Compact electric press with 1,500 lbs of pressure, ideal for smaller commercial operations

- NugSmasher Pro: 20 tons of pressure with digital temperature control and lifetime warranty

When selecting equipment for commercial production, also consider the proper storage solutions for your final product, as outlined in this guide to storing rosin and live rosin.

ROI Considerations for Commercial Operations

The return on investment for a commercial rosin press depends on several factors:

Initial Investment vs. Output Capacity

Commercial presses range from $3,000 to $50,000+ depending on capacity and features. Calculate your daily processing needs to determine appropriate size and avoid overspending on unnecessary capacity.

Operating Costs

Consider power consumption, maintenance requirements, and consumables like filter bags and parchment paper. These ongoing costs impact your per-gram production expenses.

Labor Efficiency

More automated systems reduce labor costs but come with higher initial investment. Evaluate how many operator hours each model requires per kilogram of processed material.

For operations focused on creating premium products, understanding the starting material is crucial. Learn more about finding the best weed strains for quality rosin to maximize your press investment.

Maintenance Tips for Longevity

Proper maintenance extends the life of your commercial press and ensures consistent performance:

- Clean plates after each use while warm (not hot) to remove residue

- Regularly inspect hydraulic systems for leaks or pressure inconsistencies

- Calibrate temperature controllers quarterly for accuracy

- Lubricate moving parts according to manufacturer specifications

- Keep detailed maintenance logs to track performance changes

Following a regular maintenance schedule prevents costly downtime and extends equipment lifespan, making your initial investment more valuable over time.

Future Innovations in Commercial Rosin Technology

The commercial rosin press market continues to evolve with several emerging trends:

- AI-Driven Pressure Control: Systems that adjust pressure based on material feedback

- Integrated Analytics: Built-in yield tracking and production metrics

- Energy Efficiency: Lower power consumption while maintaining performance

- Multi-Material Processing: Specialized plates for different starting materials

As consumer interest in solventless concentrates grows, manufacturers are responding with more sophisticated equipment. Staying informed about these advancements helps commercial processors remain competitive in a rapidly changing market.

Whether you're upgrading existing equipment or building a new production facility, selecting the best commercial rosin press requires careful consideration of your specific needs, growth projections, and quality standards. By focusing on the features that matter most for your operation, you can make an investment that delivers consistent returns through improved efficiency and product quality.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.