Replacement parts & accessories for cannabis machinery are essential for ensuring consistent performance, reducing downtime, and extending the operational life of processing and packaging equipment. From automated pre-roll fillers and heat sealers to grinders and extractors, cannabis operations rely on high-functioning machines that require routine maintenance and timely part replacement. Stocking the right components, tools, and upgrades ensures production remains uninterrupted, compliant, and scalable as demand increases.

Why Replacement Parts Matter in Cannabis Operations

Cannabis machinery operates under high-volume and often high-precision conditions. Wear and tear on moving parts is inevitable, especially in continuous-use environments like commercial cultivation and processing facilities. Replacing worn-out parts before failure minimizes the risk of unplanned outages and costly repairs.

- Prevents breakdowns: Routine part replacement reduces unexpected equipment failures

- Maintains product consistency: Ensures precise filling, sealing, or trimming every time

- Preserves machine warranties: Using manufacturer-approved parts keeps service agreements valid

- Reduces downtime: On-hand spares accelerate maintenance and repair timelines

- Improves compliance: Properly functioning machines support regulatory requirements

Common Replacement Parts for Cannabis Equipment

The specific replacement parts & accessories for cannabis machinery you need depend on the type of equipment used in your facility. However, some parts are universally critical across machinery types:

- Sealing elements: Heat sealer bars, gaskets, and wiring for mylar bag sealing machines

- Grinder blades: High-performance blades and screens for dry flower grinding

- Filling nozzles and syringes: Precision nozzles for vape cartridge or edible filling

- Motors and belts: Drive components for trimmers, conveyors, and labeling machines

- Temperature sensors: Thermocouples and thermostats for extraction or infusion equipment

- O-rings and seals: Critical for maintaining pressure and cleanliness in extractors

Identifying high-use components early allows operations to proactively manage inventory and avoid bottlenecks.

Accessories to Enhance Machine Performance

In addition to replacement parts, accessories can improve machine functionality, streamline workflows, and enhance output:

- Adjustable trays and holders: Allow for faster changeovers between product sizes

- Pre-roll cone loaders: Boost efficiency in pre-roll manufacturing lines

- Cleaning tools: Brushes, swabs, and solvents to maintain machine hygiene

- Calibration kits: For precise measurement and accuracy in filling machines

- Custom molds or dies: Tailored parts for gummies or tablets in edible production

Optimizing accessories enhances both speed and quality, helping brands scale production with consistency.

Types of Cannabis Machinery That Require Routine Maintenance

Nearly every stage of cannabis processing relies on specialized machinery that requires regular upkeep. Common equipment categories include:

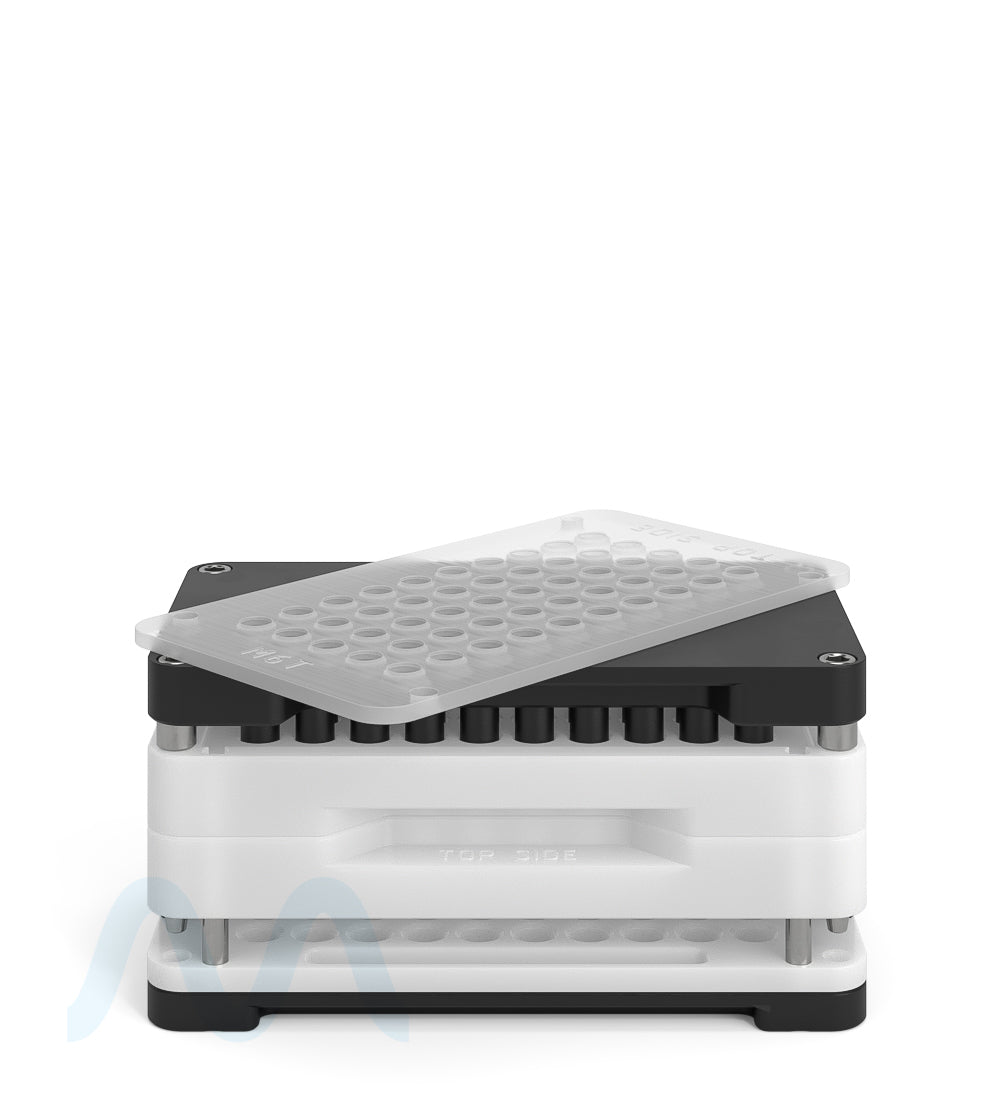

- Pre-roll filling machines: Cones, funnels, tampers, and vibration plates wear with use

- Heat sealing machines: Heating elements, blades, and silicone pads must be replaced periodically

- Cartridge filling systems: Syringe plungers, dosing nozzles, and PTFE tubing degrade over time

- Grinders and shredders: Cutting surfaces must remain sharp for consistent particle size

- Extraction systems: Pumps, hoses, and pressure gauges require calibration and part swaps

Maintaining these machines ensures clean, precise, and safe production environments.

How to Source Reliable Replacement Parts

Finding the right parts means balancing quality, compatibility, and availability. Consider the following when selecting a vendor or manufacturer:

- OEM compatibility: Choose parts verified for your specific machine model

- Lead times: Confirm availability and shipping timelines to prevent downtime

- Bulk discounts: Stock frequently replaced items in advance at wholesale prices

- Technical support: Work with vendors that offer installation or troubleshooting guidance

- Warranty protection: Ensure parts meet safety and performance standards

Establishing a parts inventory program can dramatically improve operational continuity.

Maintenance Schedules and Best Practices

Preventive maintenance supported by replacement part planning extends the life of cannabis machinery. Here’s how to stay ahead:

- Log part usage: Track wear and tear to predict replacement cycles

- Schedule inspections: Weekly or monthly reviews reduce surprise breakdowns

- Train technicians: Ensure staff can safely replace parts without damaging machines

- Use part labels: Organize spares with item numbers and install dates

- Follow manufacturer guidelines: Adhere to suggested maintenance intervals

These best practices help avoid production delays and keep compliance on track.

Conclusion: Streamline Cannabis Production with Quality Parts and Accessories

Reliable replacement parts & accessories for cannabis machinery are essential for efficient, safe, and scalable cannabis operations. From pre-roll assembly to extraction and final packaging, each piece of equipment plays a critical role—and so do the components that keep them running. By sourcing high-quality parts, maintaining an organized inventory, and investing in accessories that enhance performance, cannabis brands can protect their equipment investment, increase output, and minimize costly interruptions across their production lifecycle.